About us

Slavutych Technology is an engineering company that focuses exclusively on Tramp Metal Detectors for enterprises processing magnetite and other ores. For almost 30 years, we have been designing and manufacturing the BARRIER metal detector line, created to solve a key task of the mining industry - stable detection of tramp metal in the flow of magnetite iron ore. Since 1997, we have installed almost 1000 different types of metal detectors to work with various types of ore.

We are a family company of engineers and researchers. Decades of field use of our equipment at mining and processing plants, together with continuous R&D, allow us to improve system stability, implement the latest technologies, and keep moving forward technologically.

Our mission is to help permanently solve the problem of equipment and conveyor belt damage caused by tramp metal at ore-processing enterprises. Our technological advances overcome the problems that have limited conventional metal detectors for decades.

History & Milestones або Company Timeline

-

Founding of the Company

The company was founded as Scientific and Technical Enterprise - Slavutych. At the same time, we developed a prototype of a conveyor metal detector.

-

Release of the first tramp metal detector — BARRIER-104

Within a short time, several prototypes were built, and the first BARRIER-104 metal detector was presented and installed at an industrial site.

It was designed to operate on riveted belts, offered high resistance to electromagnetic interference, and focused on detecting manganese steel.

-

Development of a New Metal Detector Model for Magnetite Ore

Start of development of a dedicated metal detector for magnetite iron ore, integration of modern digital and analog technologies, and creation of the first prototypes.

-

Release of the BARRIER-404 Metal Detector for Magnetite Iron Ore

After successful testing of the first four units at the crushing plant of a magnetite iron-ore concentrator, the detector received the 404 model index and was put into production.

All four Tramp metal detector BARRIER-404 units were installed in a row, spaced 5 m apart, with an ore burden height up to 600 mm on a 1400 mm belt.

-

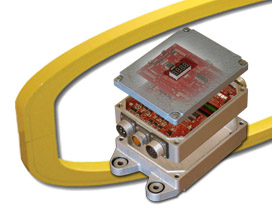

Release of the Next Model - BARRIER-407

A substantial upgrade over the 404: BARRIER-407 introduces DSP processing, which significantly improves performance when handling iron ore with Fe content up to 70%.

Support for steel-cord belts has also been added.

-

200 BARRIER installations!

Such a number of installations confirms the reliability and effectiveness of BARRIER.

-

Starting development of a new model BARRIER-408

To boost efficiency and reduce commissioning time, development of the next generation, the BARRIER-408 series, has begun.

-

New RevolutionaryBARRIER-408 model released

The “plug-and-forget” principle is now a reality: automatic adjustment for ore type, steel-cord belts, sensitivity, and vibration. No manual calibrations, no coil balancing, no ore tuning — everything is handled automatically. This dramatically reduces both staff training time and commissioning time.

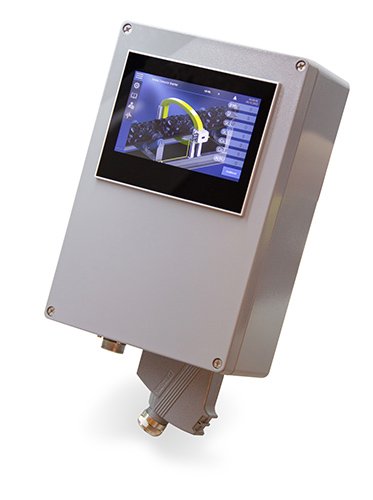

Control of the BARRIER-408 can also be performed remotely at distances up to 500 meters, using a touch keypad with a 3-inch color display.

-

Expanding Export Sales

Thanks to the fact that BARRIER-408 metal detector does not require specially trained personnel for installation and commissioning, and due to its automatic settings, our direct export sales to end users have increased significantly. From now on, in addition to magnetite, we have proven operating experience on copper and gold ores.

-

400 BARRIER installations!

400 field installations—clear proof of BARRIER’s reliability and effectiveness.

-

BARRIER-409 development has started

Beginning development of a revolutionary new model that brings together all the latest technologies.

-

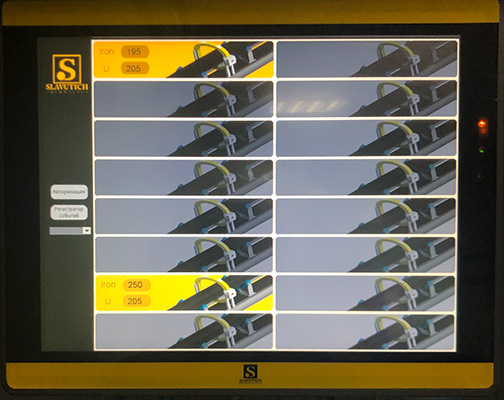

Big project launched: Control system for 16 metal detectors Barrier

A purpose-built control system for control 16 BARRIER metal detectors Barrier-408 installed within a single facility—a crushing plant for secondary and tertiary crushing of magnetite iron ore.

All 16 detectors are located close to each other (belt width 1400 mm, burden depth 600 mm).

-

The new, game-changing BARRIER-409 released

Revolutionary model incorporating the latest technologies

No ore influence on sensitivity — remarkably, even magnetite ore no longer reduces the detector’s response to tramp metal. Control is performed via a 7-inch multi-touch real-time system, remote access over the LTE Internet, an Event Log, and the powerful Real-Time Data Analyzer, which visualizes how the detector “sees” electromagnetic and mechanical interference, ore, and metal in real time.

The search coil has also been redesigned: a modular construction makes installation even easier, while its 360° magnetic-field coverage ensures a uniform field, leading to smoother, more stable, and predictable results

-

750 BARRIER installations!

We’re ramping production and expanding installations, with legacy BARRIER-404 detectors still operating reliably on magnetite for 20+ years.

-

Built-on Internet LTE acess to Barrier Tramp Metal Detector released

-

Released Tramp Metal detector Barrier for ultra-wide conveyor belts — up to 3200 mm

Our technology allows coils in virtually any size. Even better, they’re fully interchangeable and universal: the BARRIER electronics automatically recognize the connected coil and configure it optimally, thanks to unified modules.

-

940 BARRIER installations!

Almost 1,000 metal detectors produced and delivered to customers!

-

Development of the Tramp Metal Detector BARRIER-410 has started

Relentless progress. Coming soon.