Tramp Metal Detector

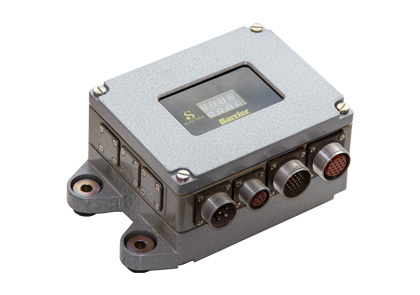

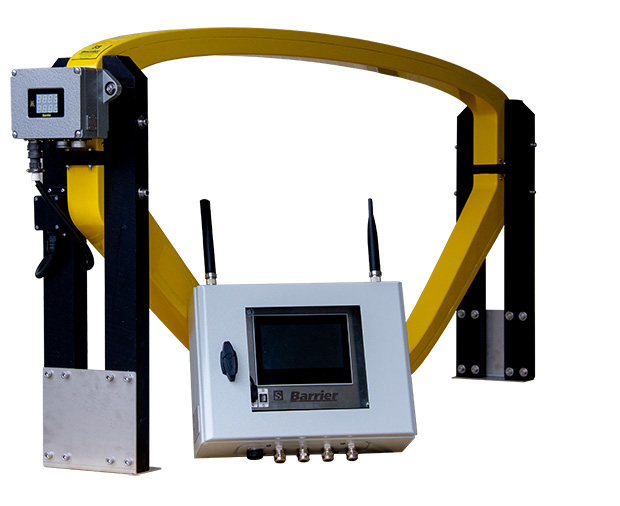

Metal Detector Barrier409FE

BARRIER is designed specifically to work with the most challenging materials — magnetite iron ore, iron concentrate, and iron pellets—with iron content up to 70%. It is intended to protect conveyor belts and cone crushers from damage by tramp metal, especially non-magnetic manganese steel (from which excavator teeth and drill bit crowns are made).

Cutting-edge, unique technology enables tramp-metal detection in the ore stream with no loss of sensitivity or performance.

Conversion module 2M409F

The main module performs the metal detection function, DSP processing, filtering of electromagnetic and mechanical interference, automatic magnetite ore adjustment, stream processing of changes in ore composition, sensitivity correction, and calculates the size and length of the detected metal and its distance from the conveyor coil.

Conveyor search coil1D204

The metal detector’s split search coil consists of two halves that are assembled in situ on the conveyor. It is contoured to follow the conveyor belt, and its 360° magnetic-field coverage allows the field to penetrate beneath the ore without loss of signal strength while providing exceptional immunity to electromagnetic and mechanical interference.

The coil requires no balancing or adjustments, has no tuning elements, is completely immune to vibration, and works immediately “out of the box.”

Belt clip detector module1С503

Installing the belt clip detector enables the tramp metal detector BARRIER to automatically recognize belt splices

This allows detection of tramp metal of the required dimensions on riveted belts without any loss of sensitivity—even at the splice itself.

Belt clip detector module1C505

The BARRIER tramp metal detector can operate on steel-cord belts just as well as on standard conveyor belts even when conveying magnetite iron ore.

Control module3В409Е

Control of the metal detector is provided via a 7-inch multi-touch HMI with a real-time system, multiple network interfaces RS-485, Ethernet, and remote LTE access for rapid service, diagnostics, and monitoring.

The control module can be installed up to 100 m from the search coil.

Features

Ore metal detector

FAQ

The BARRIER tramp metal detector was originally designed for high-Fe ores. It is a dedicated detector for magnetite ores with unique technology. It automatically adapts to magnetite and hematite flows (including fines) and maintains sensitivity without re-tuning, even when Fe content fluctuates up to ~70%. All of this is achieved without any loss of sensitivity! In other words, the sensitivity on limestone and on magnetite will be the same!

The BARRIER automatically adapts. Changes in metal content in the ore do not require manual re-tuning; everything happens automatically.

Yes. Operation on steel-cord belts is supported by design. The detector automatically compensates for steel-cord splices and will be ready to work with the same sensitivity as on regular fabric belts.

Yes. Detection of non-magnetic manganese steel (excavator teeth, drill bits, crusher wear parts) is a key use case.

The BARRIER metal detector can detect metal not only by size but also by length, thereby preventing conveyor belt damage caused by long rods piercing the belt at transfer points.

No, the coils do not require manual balancing. Moreover, all modules are universal: you can simply replace a coil for BW 800 mm with a coil for BW 3000 mm, and everything will work immediately after the detector is powered on.

Extremely easy! This is the first time a tramp metal detector is as easy to commission as, for example, a printer. You just need to power it on—and that’s it! Within the first 20 seconds the detector adapts to everything and is ready to detect metal, and the default settings are suitable for most iron ores.

Graphic interface

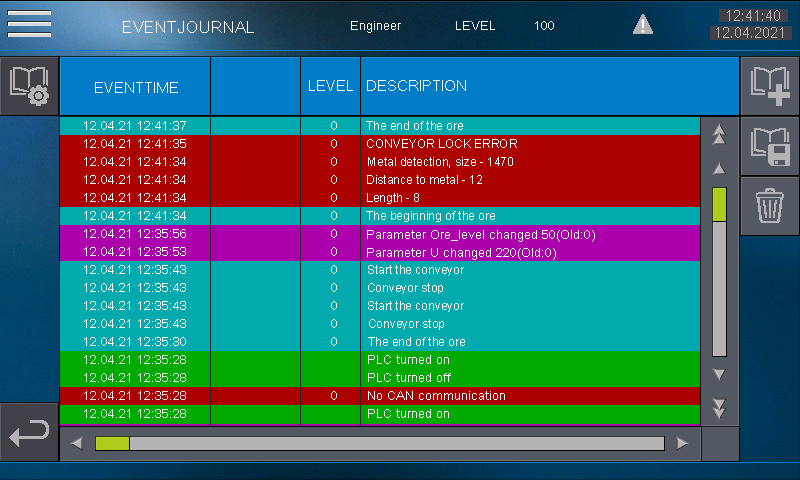

The control of the metal detector "Barrier-409" is performed through the graphical interface of the control module 3B409E which is based on a real time system and provides the following additional features:

- Data visualization

- Ore autotune

- Steel-cord autotune

- Event log

- Access control

- LTE Internet diagnostics

- USB software update

Auto-tune in case of the ore change.

In the case of ore changes, auto-tuning is performed by online control of the content of a useful component in iron ore raw materials, comparing the obtained data with the predetermined product profiles and automatic switching of the profiles.

Conveyor state

Event Log

The event log captures all events occurring with metal detectors, sorts and stores them in internal memory with the ability to export to a USB drive:

- Conveyor stop lockout error

- Сhange settings

- Size, length and distance to the detected metal

- Ore on the conveyor

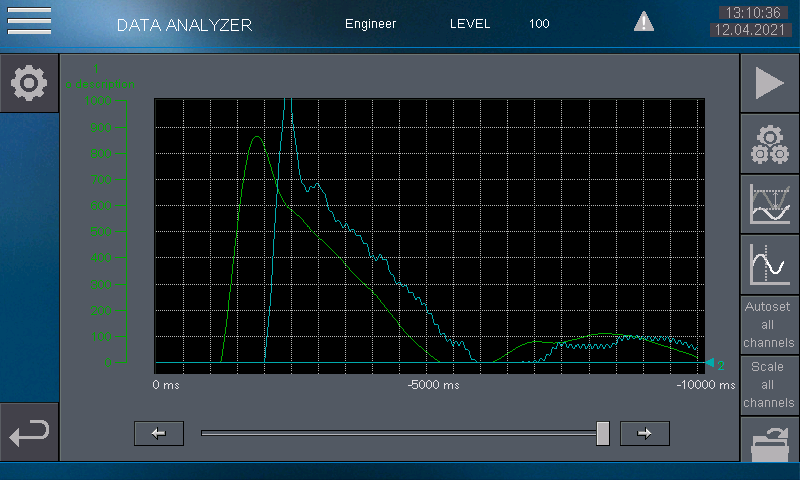

Data analysis

Real-time visualization of metal detector data, with the ability to display by trigger, fix and scale each channel allows the technical specialist of the enterprise or the service of Slavutich Technology LLC to make a fine-tuning or determination:

- conveyor state

- impact of ore

- belt properties

- welding effect

- conveyor belt condition

Remote diagnostics

The built-in solution allows either our service team or the customer’s team to access the BARRIER remotely from anywhere, on request.